Save Time and Increase Efficiency with LightForce’s Custom Rebond IDB Trays

When it comes to orthodontics, precision is paramount. And that means not just ensuring that braces are applied precisely at the start of a treatment, but also maintaining that same level of precision when rebonding brackets if they do break. Unfortunately, most traditional orthodontic products provide limited support for this critical stage, meaning that rebonding is often highly manual, time-consuming, and imprecise.

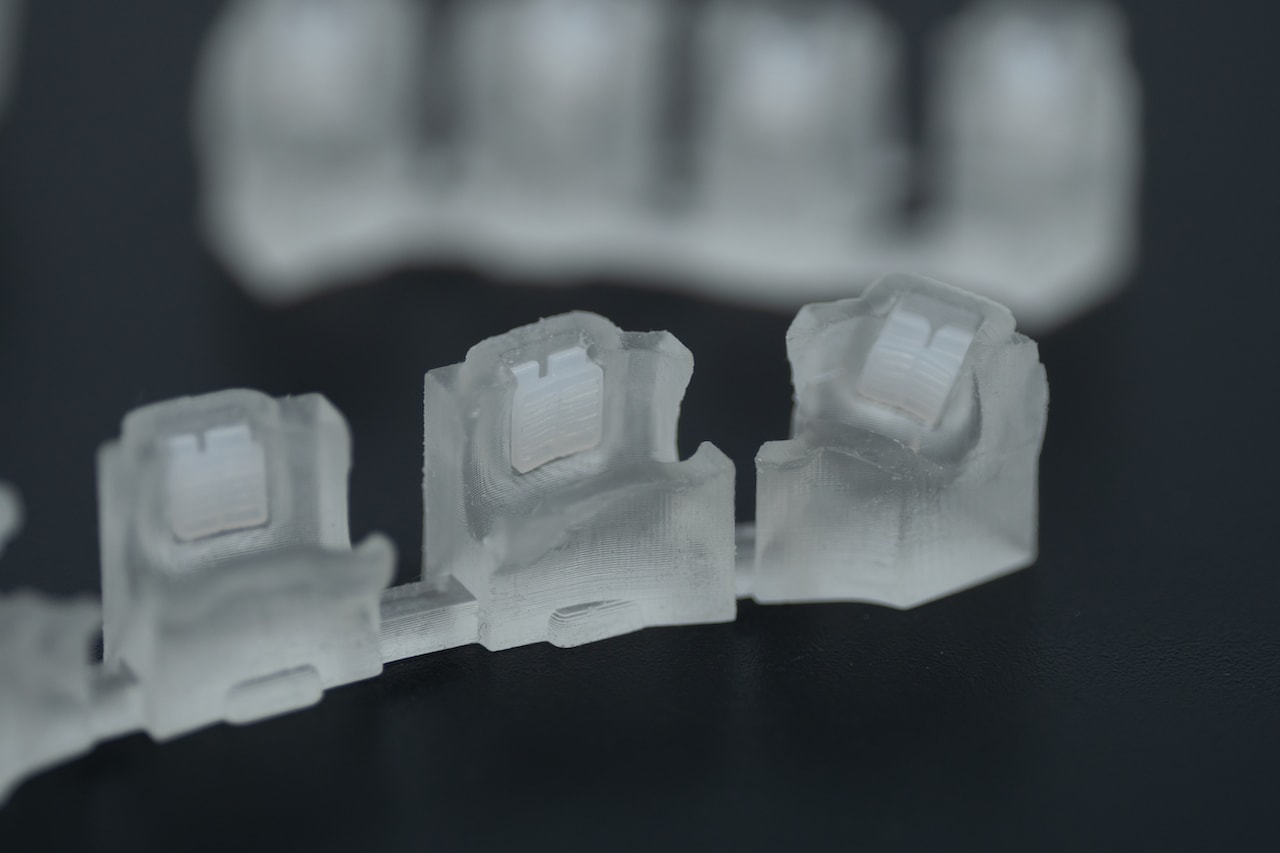

That’s why LightForce includes a fully-customized rebond tray along with every set of its custom-built, 3D-printed brackets. Just like LightForce’s flagship brackets and indirect bonding trays, our rebond trays are manufactured to match each patient’s unique tooth morphology, ensuring a perfect fit every time. The rebond tray has an occlusal shelf that makes it easy for the orthodontist to apply pressure during bonding, and you can easily remove the tray from the patient’s mouth once the bonding is complete without any need for additional cleanup. In addition, the tray’s bridges are flexible, but tough to break, so you can maneuver them as needed but you don’t have to worry about accidentally snapping them during the rebonding process.

Orthodontists can achieve new levels of precision with LightForce’s custom-built rebond trays, which are manufactured to exactly match each patient’s teeth.

With LightForce’s rebond trays, you can create segments for individual teeth or groups of teeth, and you can track which segment corresponds to each tooth in order to more easily replace broken brackets. The rebond trays can also be used regardless of the positions of the surrounding teeth, brackets, or bite turbos, meaning that your patients will get top-notch accuracy regardless of their particular situation or how far along in their treatment plan they happen to be. And most importantly, these rebond trays now come included with every set of LightForce braces as a part of our standard box of replacement parts, so you’ll always have the tools you need to reattach broken brackets as soon as the patient calls in.

LightForce’s rebond trays come pre-segmented, and they can be further segmented into individual teeth sections to meet the unique needs of each patient and case.

While it can be challenging to achieve high levels of accuracy with traditional, direct bonding techniques, our rebond trays enable superior precision without the need for labor-intensive, manual reattachment procedures. It’s easy for anyone to learn to use our rebond trays, which means that orthodontists can delegate rebonding to other staff members, ensuring that patients get high-quality care while saving coveted doctor time for the most critical cases. The ability to simplify and delegate these recurring, time-critical tasks means that you can get back in the driver’s seat of your practice, and spend your time where you can make the biggest impact on your patients.

LightForce’s rebond trays give the orthodontist control over the parts of clinical work that are hardest to predict and provide numerous benefits to both doctors and patients. Specifically, the trays are:

- Patient-specific

- Biocompatible

- Precisely fitted to each individual tooth, with brackets included

- Easily delegated to staff members

- Built to enable more-accurate bracket placement than direct bonding for individual teeth

- Labeled with the palmer notation, and attached with 3D-printed bridges that can be separated as needed

- Shipped in a convenient replacement parts box for easy organization and storage

Ultimately, our rebond trays empower you to provide a level of efficiency and precision that’s unmatched in the industry, improving both your effectiveness and the patient’s experience. You never know when a patient will make the mistake of taking a bite of a particularly crunchy carrot, or when a stubborn bracket will pop off for seemingly no reason at all. But with our rebond trays and box of customized replacement parts, you and your team will be prepared to get that bracket reattached at a moment’s notice — and you’ll be empowered to get back to doing the work you’re meant to be doing.

Want to learn more about LightForce Orthodontics and our 100% custom-designed brackets and rebond trays? Take a look (or a listen) to this recent interview with LightForce CEO Dr. Alfred Griffin, or contact us today for more information.